12% boost in truck cycles

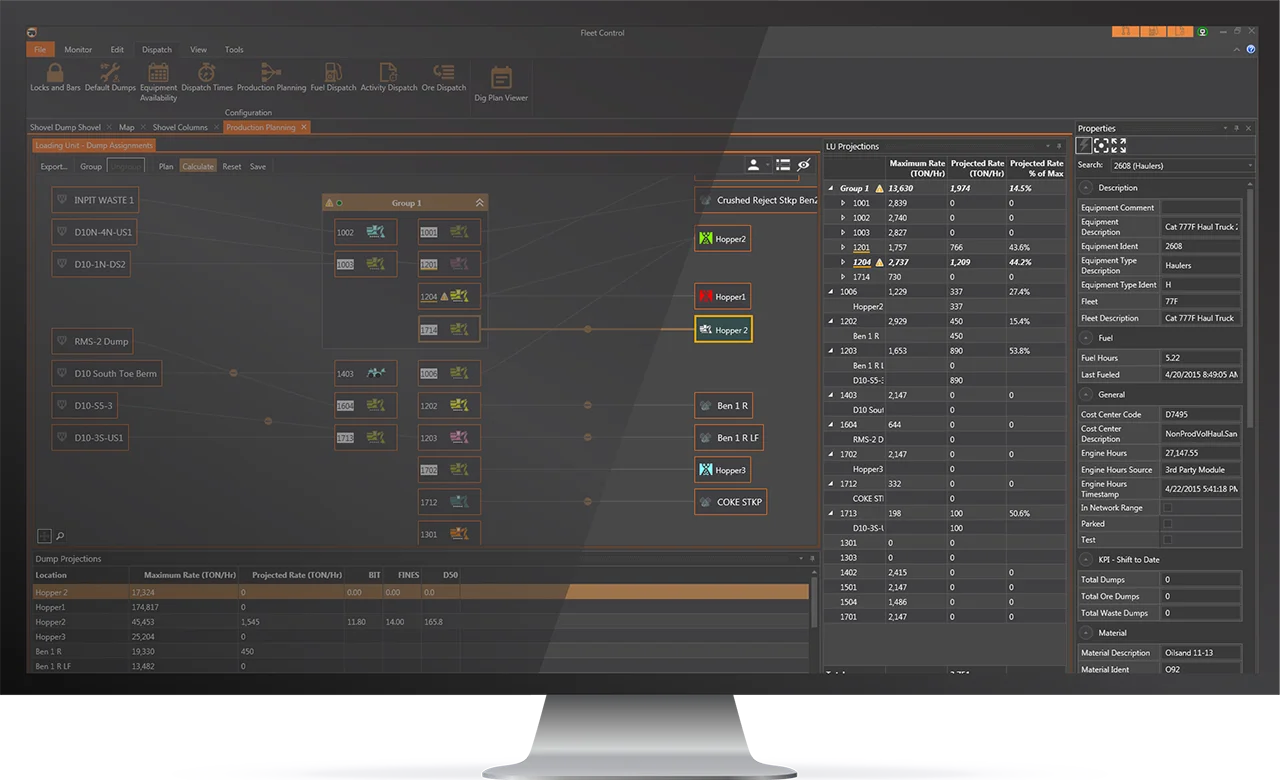

Dynamic dispatching assigns your trucks to the best load and dump points for your site’s needs every time.

Configure your preferences and let the system deliver more material, reduce equipment needed, lessen wait time, or achieve another KPI for your operation.

Running dynamically, most mines raise their truck cycles 12% or higher — producing more material in the same time using the same equipment.